Healthy Building Materials Research

Building Products Material Vetting: Looking at product health, hazards and sustainability.

With today’s options for building materials, picking the right product can prove difficult, even if you know what you are looking for. This article will examine the changes happening in the building materials industry and provide guidance on selecting products that will meet the goals of your project.

In recent years, the increased awareness in sustainable design has broadened industry wide concerns with the health hazardous of building materials. As with past products contained harmful chemicals such as asbestos, PCBs and formaldehyde, building designers understand that not all products are created equal, and many products are not fully vetted for human and environmental health effects until years after they have been installed in millions of buildings. So as health concerns continue, understanding what chemicals are in our building products is moving up on the priority list and becoming just as important as knowing what is in the food we eat. Many programs and certifications have evolved to evaluate products for chemical composition, environmental and human health which are helping to allow professionals to cross compare products.

In the last ten to twenty years, the Passive House (Passivehaus) standard and energy efficient design strategies have made airtightness a greater priority to achieve higher levels of energy efficiency. However, with a tighter building envelope, there is less natural air leakage and less fresh outside air coming in. We need tight envelopes to maintain comfortable temperatures, while minimizing heating and cooling output. Though one of the problems with building tighter is that many of the products we put into our buildings, are full of harmful chemicals. Once installed, many chemicals off-gas into the building and contaminate the indoor air. Where older leaky buildings allowed for these chemicals to flow out of the house, newer buildings must now integrate efficient mechanical air ventilation strategies in order to reduce chemicals and improve indoor air quality while still maintaining interior temperatures. In addition to building energy efficiency, increased concerns for overall human health and wellness are playing a big part in moving the building materials industry into a realm of greater transparency and concern for what exactly goes into each product. So if we can easily select products that don’t contain known chemicals of concern, or maximize the use of natural ingredients, less concern needs to be paid to what might be in the air of our home or office.

With millions of building products on the market today, it’s often difficult to know where to start. For do-it yourself-ers and smaller builders, what’s available at Home Depot and Lowes typically determines which products get used, with little regard for material health or sustainability. For commercial and larger scale projects, the search for the perfect product can seem almost infinite. Every day more products become available, and there is a overabundance of differnt claims of sustainable and healthier products: PVC free, NAUF, GreenGuard Certified, recycled content %, FSC, FloorScore, low VOC, etc. . There are literally thousands different criteria which get applied to products, which continue to make product comparisons more difficult. Material selection has never been a quick and easy process, but with all the additional requirements, certifications and health concerns it is quickly becoming an almost impossible task for architects and developers to be sure they are selecting the best of the best. It seems at this point, understanding building product hazards and sustainability criteria could be a university major all in itself, so the items below will simplify the process a bit to give you a better understanding of the factors at play, so you’ll be able to set realistic goals for your project.

Material Health vs. Sustainability:

Signature Sustainability has recently been providing full material product vetting for a developer in New York City. The scope of the project consisted of a full review of material sections of the specifications. Focus was given to products that have direct interaction with building occupants, such as flooring materials, counter tops, wall and ceiling materials in addition to several other more indirect products like caulking, shop applied coatings, flame retardants and adhesives. The main goal of the client was to provide a building that was considerably “healthier” than that of a standard building. Through the careful vetting of product health and sustainability criteria, we assisted the client with reviewing materials and recommending the products with the least hazardous chemicals and greatest environmental certifications or manufacturing processes.

Although we looked at both health and sustainability, the client wanted health criteria to be priority over sustainability. When attempting to select the best product in a material category, there were times when we needed to consider health criteria over sustainability in order to meet the client’s goals. When reviewing gypsum board, we knew that there is typically a large amount of recycled content, which met the project’s sustainability goals. The unfortunate discovery, is that the recycled content in gypsum board is far more hazardous than natural gypsum. (A side note: most gypsum wallboard on the east coast uses FGD (Fuel Gas Desulfurization) as replacement filler for natural gypsum. FGD is a process used to remove sulfur dioxide from fossil fuel power plants, and the material collected in the scrubbers now makes up a large portion of the recycled content in much of the east coast gypsum board. Gypsum from the west coast however, is typically natural gypsum and thus free of any FGD material.) Some research suggests that synthetic gypsum is not harmful, while other reports state that mercury and other metals are present in the product. So, in order to align with the client’s goals of improved building health, we needed to select a product with as little recycled content as possible. In this case, a product with no recycled content was actually the preferable choice. The hope is that the industry progresses, manufacturer’s will provide products meeting both health and sustainability criteria, rather than having to forgo one or the other.

Material Hazards:

In order to help to weed out products with harmful chemicals and push manufacturer’s to meet higher thresholds of material health and sustainability, many certifications and standards have evolved to make identifying products easier. The problem with so many certifications is that it can often be an overwhelming task to determine what programs apply to the material and which certifications are most effective at ensuring material health.

There are now hundreds of material health attributes to consider, some of the more popular are:

- VOC content (grams per liter g/l) – Standard in evaluating paints, coatings, sealants, adhesives. Volatile Organic Compounds are chemicals which easily become vapor and “off-gas” chemicals into the air.

- Building Product Certifications:

a. FloorScore – Flooring Products, adhesives and underlayments

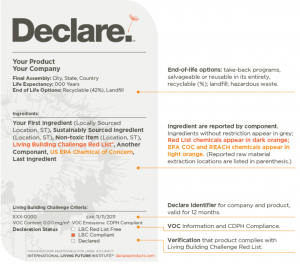

b. Declare Label – Living Futures Institute Certification (all product types)

c. GreenGuard Gold – Many Material Categories

d. Green Screen – Chemical Hazard Assessment

e. CRI Green Label & Green Label Plus+ – Carpet, Carpet Pad, adhesives

f. Cradle To Cradle – Environmental Life Cycle Analysis

g. Cradle To Cradle – Material Health Evaluations

h. SCS Indoor Advantage – Building Products, Furniture

- Environmental Product Declarations (EPDs): documents that provide additional environmental product life cycle analysis information and global warming potential information.

- Health Product Declarations (HPDs): documents, which indicate the percentage and type of chemicals used in production along with associated hazards. (expanded beyond what is covered in MSDS or SDS)

- SDS & MSDS (Safety Data Sheets & Material Safety Data Sheets) – standard building product health criteria and emergency information.

- Typical Chemicals of Concern:

- Mercury

- Lead

- Flame Retardants (Polybrominated diphenyl ethers (PBDEs))

- Polychlorinated biphenyls (PCBs)

- Chlorinated Pesticides

- Phthalates (PVC)

- Formaldehyde

- Anti-microbials

- Fly-ash or FGD

- The Red List (Living Futures Institute and Declare Labels) this list includes a preselected list of chemicals of concern. These chemicals are banned from use on Living Building Challenge projects.

- Indoor air standards: CDPH 01350 – California Department of Public Health sets standards for environmental and public health considerations. Some key elements focus on indoor air criteria used by GreenGuard and other certification programs as a baseline for improved indoor air quality standards.

- Database: Pharos Project – “combines manufacturer transparency and independent research to provide in-depth health and environmental information about a wide range of building products.”

Material Sustainability:

With so many levels of health and sustainability criteria to consider, selecting the right product can seem daunting. How do you ensure you select the most sustainable product for environmental health, in addition to making sure you don’t select a product that might contain known carcinogens, while also ensuring the product will earn you credit towards LEED, WELL or Living Building Challenge or meet your general project goals? You may want to dive in and do the research yourself, but be sure to take that time into consideration. Hundreds, if not thousands of hours can be spent researching products in order to determine what is available and what meets your project’s requirements. Signature Sustainability well versed in building materials vetting and understand the importance of selecting the least hazardous and most sustainable products. It may be wise to make a list of the products you are most concerned with and start there.

When looking at the environmental sustainability of products, the best products tend to be from manufacturers that provide transparency about what goes into their manufacturing process. If there are no harmful chemicals in a product a manufacturer shouldn’t’ be worried about disclosing what is in the product on a Health Product Declaration (HPD). If the manufacturing process limits transportation, uses recycled or rapidly renewable products the Environmental Product Declaration (EPD) will indicate as such.

Some of the current standard sustainability criteria of products:

- FSC WOOD – (Forest Stewardship Council): sustainably harvested wood, invoices should indicate a Chain of Custody number (COC).

- Recycled Content – varies from pre-consumer (post industrial) and post-consumer (pre-industrial). Ask your manufacturer what makes up the reused material.

- Biobased content – many products are manufactured using waste from the agriculture industry. Materials that are derived from biomass resources. (Organic materials such as crop residues, wood residues, grasses and aquatic plants.) The USDA has created standards for “BioPrefered” products. More information in the link.

- Rapidly Renewable – products which are able to regenerate in less than 10 years

- Product Transparency: HPDs and EPDs – these documents provide product disclosure for health and environmental criteria provided by manufacturer’s and third party testing agencies.

- Local Products – products manufactured as close to the project site are beneficial in that they support the local economy as well as reduce distances required for transportation, cutting down on total life cycle carbon emissions.

- Energy Star – Energy Efficient Appliances

In closing, there are always choices to be made with regards to a specific project goals and needs. Currently, the industry is undergoing a important shift towards improved wellbeing and sustainable criteria. As the demand for products that meet enhanced levels of health and environmental standards increase, manufacturers will continue to shift their focus to modifying their products to follow suit. It is important to call your manufacturer representatives and speak with them about what your project is looking to do and what type of documentation and criteria you are looking for. Many of our conversations with manufacturers have been beneficial to educating them on changes in the industry and allows them the choice to pursue new methods of product creation and chemistry. Communication is key toward getting the product supply to catch up with the demand for better building products. Material vetting may always be an overwhelming task, but product databases like Pharos, certifications and transparency should help to make it easier in the years to come.

If you have any questions, please don’t hesitate to reach out: ian@signaturesustainability.com